THE POLYDUCTOR

The Polyductor is engineered specifically for polymers and other difficult to wet materials.

It generates high conveying air flow. The design transport velocity is 3000 ft/min. The high velocity scrubs the suction tube clean. The tube is made of Teflon to prevent polymer sticking. The Teflon is translucent for quick visual inspection.

High speed collision between the polymer granules and the water stream assures thorough dispersion and wetting. This results in faster hydration and minimizes the required aging time for maximum polyner activation.

The water jet scrubs the air of all dust particles.

Internal surfaces are continuously flushed to prevent build-up.

Polyductor will draw polymer up to 15 feet vertically and 30 feet horizontally.

CAPACITIES:

Dilution Water Flow: 10, 20, 40, 80 GPM.

Polymer Feed Capacity: up to 1.5 lbs/min.

Water pressure range: 40 to 100 psig.

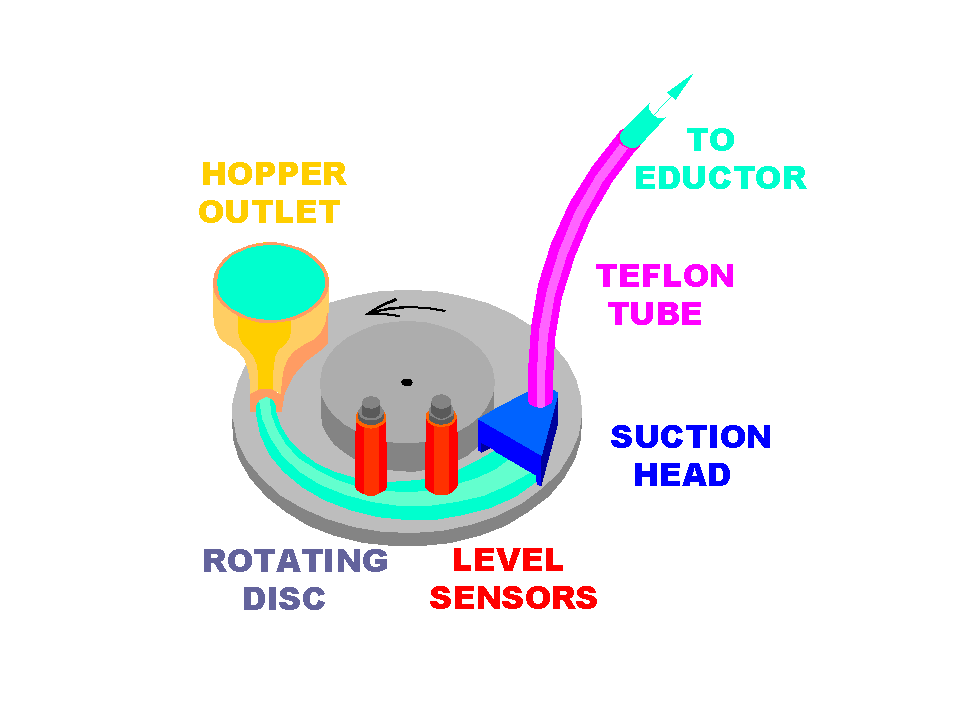

ROTATING DISC COMPONENT

The disc is continuously vacuumed clean to prevent build-up.

The polymer flow is steady. It does not pulsate as with screw feeders.

All components are easy to access. The feeder does not need to be dis-assembled if it ever needs to be cleaned.

Sensors monitor polymer levels on the disc.

The polymer flow rate and the amount fed per batch are easy to change.

The feeder is totally enclosed.

A clear door on the enclosure allows the operator to see the feeder.

An air dryer keeps the humidity low in the feeder enclosure and the hopper.

Standard hopper capacity is 2.7 cu. ft. ( 76 L. ). Other are available.

Standard feeder ranges are: 3, 6, 12 lbs/min. Other are available.

The modular design can be adapted for existing or new facilities.